المنتجات الساخنة

The Process of Mining Bauxite Dajcor

网页2019年2月27日 Extrusion process. Step 1. Billet Pre-heating. Billets are first cut to the desired length based on the product specifications. Then billets are moved to a tunnel heater and must be heated to approximately 800-925° F. The exact temperature is based on

Contact

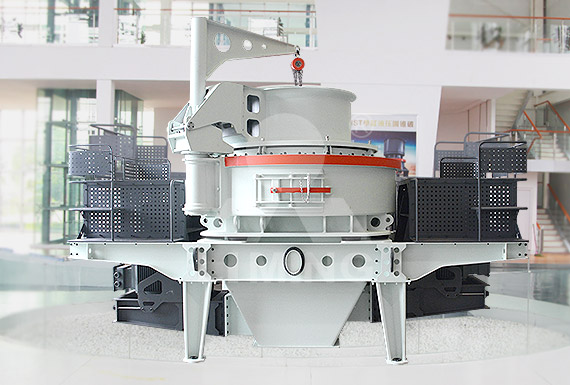

Physical Bauxite Processing: Crushing and Grinding of Bauxite

网页2022年1月23日 3.1 Introduction to Crushing and Grinding of Bauxite. The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the

Contact

Bauxite: Geology, Mineralogy, Resources, Reserves and

网页2022年1月23日 Bauxite deposit: geometrically defined space, geological unit composed of the bauxite body and its associated formations.In practice they are the subjects of the

Contact

Bauxite Mining The Australian Aluminium Council

网页The first step in producing aluminium is mining this ore. Bauxite occurs mainly in tropical and sub-tropical areas, like Africa, the Caribbean, South America and Australia. Australia is the largest producer of bauxite, with

Contact

Modeling of Bauxite Ore Wet Milling for the Improvement of Process

网页2021年9月5日 Size reduction is a necessary operation in mineral processing plants and provides the desired size for separation operations and the liberation of the valuable

Contact

Bauxite Mining and Alumina Refining PMC National

网页2014年5月8日 PROCESS DESCRIPTION: BAUXITE MINING. Bauxite is the principal ore of alumina (Al 2 O 3), which is used to produce aluminum (Al). It is composed of hydrated

Contact

Bauxite Mining, Refining, Alumina Britannica

网页bauxite, rock largely composed of a mixture of hydrous aluminum oxides. Bauxite is the principal ore of aluminum. Bauxites vary physically according to the origin and geologic history of their deposits: some deposits are

Contact

Bauxite Mines an overview ScienceDirect Topics

网页Approximately 98% of the alumina produced worldwide is manufactured via the Bayer process, which consists of digestion and calcination. Initially, the bauxite is washed and

Contact

Eco-restoration of bauxite mining: An ecological approach

网页2022年1月1日 Bauxite [Al(OH) 3] is a mineral that is used for the extraction of aluminum through surface mining or opencast mining.Different forms of bauxite such as mixed

Contact

Aluminum processing History, Mining, Refining,

网页He continued work on a second successful process that produced an aluminum-copper alloy. Conveniently, in 1888, an Austrian chemist, Karl Joseph Bayer, discovered an improved method for making pure alumina

Contact

Bauxite Properties, Formation, Uses ?

网页Bauxite is a sedimentary rock mineral that is the primary source of aluminum. It is formed through the weathering of aluminum-rich rocks in tropical and subtropical regions. The name bauxite is derived from the

Contact

Aluminium Geoscience Australia

网页2 天之前 In almost all commercial operations, alumina is extracted from the bauxite by the Bayer refining process. The process, discovered by Karl Josef Bayer in 1888, consists of four stages. Digestion: the finely ground

Contact

Bauxite 101 The Aluminum Association

网页Bauxite is primarily comprised of aluminum oxide compounds (alumina), silica, iron oxides and titanium dioxide. Approximately 70 percent of the world’s bauxite production is refined through the Bayer chemical process into alumina. Alumina is then refined into pure aluminum metal through the Hall–Héroult electrolytic process. Mining bauxite

Contact

Understanding the impacts of mining on ecosystem

网页2021年3月1日 Mining activities can pose negative, sometimes irreversible damage to ecosystems, yet consequences for ecosystem services (ES) and their contribution to human wellbeing are more uncertain. Obtaining a clear understanding of where and how mining impacts ES and the methods used to show this is crucial for determining management

Contact

Bauxite Mining Process Analytical Solutions Malvern

网页2018年3月29日 Available alumina and reactive silica define ore grade and conditions for bauxite refining. Malvern Panalytical’ s predictive solutions help to efficiently sort and blend bauxite, ensure optimal and profitable extraction of available alumina, and support sustainable and safe waste management (red mud). Our expertise and solutions range

Contact

Mining and Refining Responsible Sourcing

网页Bauxite mining emits, on average, less than 100 kg CO 2 per tonne of bauxite. Mine operators have adopted a number of strategies to use energy more efficiently and to reduce emissions. These strategies include: Purchase of larger, more energy efficient mining equipment and trucks; Improved maintenance of mining and transport machinery;

Contact

Bauxite Mining Process Description HeatTreatConsortium

网页Bauxite Mining Bauxite Refining Extrusion Forging Heat Treating Molten Handling Rolling . Bauxite is converted to alumina using the Bayer process. Bauxite is combined with caustic soda, lime, and steam to produce a sodium aluminate liquor. Impurities are filtered or settled out of the liquor and alumina hydrate is precipitated out of the mixture.

Contact

Restoration of Forested Lands under Bauxite Mining with

网页Mining poses a major environmental threat to tropical forest ecosystems, given its role in long-term forest degradation. Like Suriname, Guyana presents one of the less disturbed forested lands in South America. The local economy is improving, thanks to the development of mining which is primarily focused on gold, diamond, and bauxite. This, however, has

Contact

Recovery of Rare Earths and Other Valuable Metals From Bauxite

网页2016年8月11日 The actual composition of bauxite residue depends on the type of bauxite, the mining location, and the process parameters of the Bayer process. During the processing of bauxite by the Bayer process, the REEs report to the bauxite residue. The REEs are enriched in bauxite residue compared to bauxite by a factor of approximately

Contact

Mining and Refining Process International

网页Mining and Refining Process. The Bayer Process was invented and patented in 1887 by Austrian scientist Karl Josef Bayer. Two to three tonnes of bauxite are required to produce one tonne of alumina. 90% of the

Contact

Bauxite Bruker

网页2023年7月22日 Bauxite is the primary source for aluminum (Al). Ores in this group include aluminum hydroxides, gibbsite, boehmite and diaspore. It is not just the concentration of aluminum that is important for bauxite

Contact

Minerals Free Full-Text Feasibility of Recycling Bayer Process

网页2021年7月5日 The mining of layered soft bauxite under coal seams (BCS) will cause serious underground goaf disasters and surface Bayer process red mud (BRM) pollution. In order to realize the safe and efficient mining of BCS, the feasibility of recycling BRM as a backfilling aggregate was explored. A series of tests were conducted to prevent the

Contact

Bauxite: Geology, Mineralogy, Resources, Reserves and

网页2022年1月23日 Bauxite deposit: geometrically defined space, geological unit composed of the bauxite body and its associated formations.In practice they are the subjects of the mining operation. Duricrust—cuirassé: Iron rich (Fe 2 O 3 % attains as much as 60–80%) layer developed on the topmost level of the laterite section in 0.2–0.3 m thickness It is mostly

Contact

ENVIRONMENTAL ASPECTS OF BAUXITE, ALUMINA AND

网页2020年9月4日 II. ENVIRONMENTAL EFFECTS OF PRODUCING BAUXITE, ALUMINA AND ALUMINIUM 13 A. Introduction 13 B. Bauxite mining 14 1. MRN 14 1.1 Revegetation 14 1.2 Bauxite Tailings Disposal 14 1.3 Rehabilitation of Lake Batata 15 1.4 Control of solid particles emissions 17 1.5 MRN’s environmental policy 17 2. Bauxite Mining in the

Contact

Bauxite mining and alumina refining: process description and

网页2014年5月1日 PROCESS DESCRIPTION: BAUXITE MINING. Bauxite is the principal ore of alumina (Al 2 O 3), which is used to produce aluminum (Al). It is composed of hydrated aluminum oxides, hydrated aluminosilicates, iron oxides, hydrated iron oxides, titanium oxide, and silica. It contains mixtures of various minerals such as gibbsite, boehmite,

Contact

Bauxite Beneficiation: An Approach to Value Addition in Mining

网页2021年7月2日 Keeping the above characteristics in view, several west coast lateritic bauxite mines of India employ dry crushing−screening process to bring down silica content from the metallurgical grade bauxite [].Recently, a bauxite mine of Guinea known as AGB2A has also adopted the dry beneficiation procedure to cut down silica from about 7% to

Contact

Eco-restoration of bauxite mining: An ecological approach

网页2022年1月1日 Bauxite [Al(OH) 3] is a mineral that is used for the extraction of aluminum through surface mining or opencast mining.Different forms of bauxite such as mixed bauxite, karst bauxite and European type usually occur in nature. Global estimate of bauxite deposit lies between 55 and 75 billion tones with major contribution from Africa (32%).

Contact

What Aluminum Extraction Really Does to the Environment

网页2010年11月9日 Compared to producing virgin aluminum from raw bauxite, recycling old aluminum consumes just 5% of the energy and releases a mere 5% of the greenhouse gases . Infinitely recyclable, aluminum loses none of its integrity even when it is melted down repeatedly, plus, the whole recycling process can be achieved in less than 60 days flat.

Contact

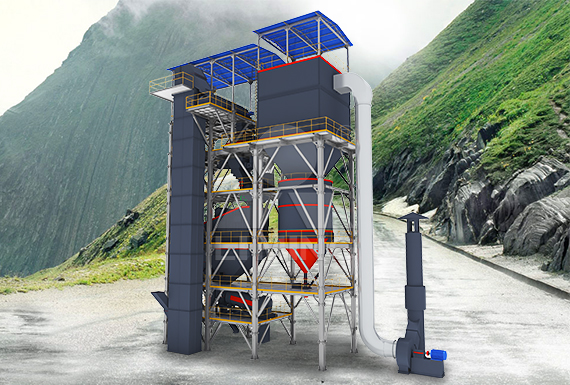

Physical Bauxite Processing: Crushing and Grinding of Bauxite

网页2022年1月23日 3.1 Introduction to Crushing and Grinding of Bauxite. The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine. The feed material is crushed or sized so that it is conveyable, as well as correctly dimensioned, for the next step in the process.

Contact