المنتجات الساخنة

Review on vertical roller mill in cement industryits

网页2021年1月1日 The raw mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier. The hot gases from the pre heater enter the mill and are used for drying material in the mills. Loesche GmbH “Operational parameters affecting the vertical

Contact

Analysis and Optimization of Grinding Performance of Vertical

网页2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters.

Contact

Modeling of vertical mill raw meal grinding process and

网页2014年7月11日 Abstract: The stability of vertical mill raw meal grinding process affect the yield and quality of cement clinker. Due to the nonlinear of grinding process, random

Contact

Operational parameters affecting the vertical roller mill

网页2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power

Contact

Efficient machine learning model to predict fineness, in a vertical raw

网页2023年3月1日 Raw meal composition and raw mill fineness are key parameters for a stable kiln monitoring. Raw meal composition is monitored in real time by an online neutron

Contact

PROCESS CONTROL FOR CEMENT GRINDING IN

网页2017年10月27日 of the raw material [1, 2]. For VRM the production capacity denotes both the capacity of grinding and drying of mill. The grindability affects the capacity of

Contact

Vertical raw mill pradeep kumar PPT SlideShare

网页2013年5月15日 Vertical raw mill K.P.PRADEEP KUMAR Sr G M Operation Karikkali Works Chettinad Cements Ltd. The principle of vertical mill resembles like ammi kallu, attaankallu, Or ennai chekku vandi. History of

Contact

PROCESS TRAINING for operators of Vertical RAW

网页PROCESS TRAINING for operators of Vertical RAW Mills . Heating of mill and grinding plant. In fact there are three processes going on in the MPS mill namely grinding, drying and clas sifying, and only when all three

Contact

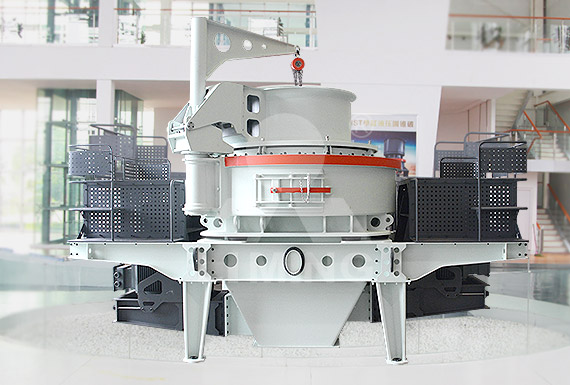

Vertical Raw Mill for Cement Raw Meal Grinding in

网页Vertical Raw Mill. Feeding size: 35-110mm. Capacity: 12-350t/h. Motor power: 255-3600kW. Applications: It can be used for grinding limestone, gypsum, siliceous, coal and other materials. It is mainly used in cement

Contact

en/manuals search pdf all vertical raw mill.md at main GitHub

网页英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Contact

Vertical Roller Mill Operation in Cement Plant

网页The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more

Contact

Vertical raw mill pradeep kumar PPT SlideShare

网页2013年5月15日 Vertical raw mill K.P.PRADEEP KUMAR Sr G M Operation Karikkali Works Chettinad Cements Ltd. The principle of vertical mill resembles like ammi kallu, attaankallu, Or ennai chekku vandi. History of

Contact

How To Install Vertical Raw Mill Crusher Mills

网页All Parameters For Vertical Raw Mill Manganese Crusher. Search all parameters for vertical raw mill to find your need. liming Mining and Construction Machinery is a global manufacturer and supplier, We supply full crushing

Contact

(PDF) ANALISIS EFISIENSI PERALATAN DAN HEAT

网页2022年7月11日 Vertical Raw Mill is a main equipment that is used in grinding or refining raw materials at PT Semen Sebagai Parameter Evaluasi Proses Kinerja Raw Mill Pada Industri Semen Jan 2019 24-28 A R

Contact

Review on vertical roller mill in cement industryits

网页2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials. With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball mill system [10].

Contact

Optimizing Raw Mills Performance ; the Materials WAY

网页2019年6月22日 Limestone 11.30,Shale 16.40 ,Bauxite 9.45,Gypsum 8.16, Silica Sand 16.46,Iron Ore 15.44,Sand stone 11.53Dolomite 11.31. * It may please be noted that the HGIBond Work Index for a

Contact

PROCESS TRAINING for operators of Vertical RAW Mills

网页PROCESS TRAINING for operators of Vertical RAW Mills . Heating of mill and grinding plant. In fact there are three processes going on in the MPS mill namely grinding, drying and clas sifying, and only when all three processes are working well the operation is smooth. Explanation of some important process parameters, process terms.

Contact

Operational parameters affecting the vertical roller mill

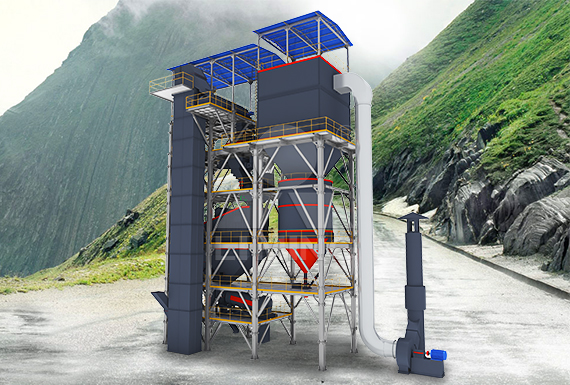

网页2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding

Contact

id/parameter kontrol vertikal raw mill.md at main lqdid/id

网页Contribute to lqdid/id development by creating an account on GitHub.

Contact

all parameters for vertical raw mill paal21texel

网页Continuously change Process Parameters and document results to. find all parameters for vertical raw mill,as the first invention was made in 488 AD. Hammer mills are used for material processing in the so I have lost pmc parameters on a 1997 Excel PMC10T24 vertical mill with . Vertical Roller Mills Fruitful. We have supplied vertical

Contact

all parameters for vertical raw mill

网页Vertical roller mill Wikipedia. Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use.Vertical roller mill has many different forms, but it works basically the same. All of these forms of machine come with a

Contact

Modeling of energy consumption factors for an industrial

网页2022年5月9日 The raw vertical roller mill has four rollers, 3000 KW main drive, 4.8 m table diameter, 2.16 m roller diameter with 330 t/h capacity (made by LOESCHE Company from Germany).

Contact

id/vertikal parameter kontrol raw mill.md at main lqdid/id

网页Contribute to lqdid/id development by creating an account on GitHub.

Contact

sbm/sbm raw mill technical parameters.md at main GitHub

网页Contribute to changjiangsx/sbm development by creating an account on GitHub.

Contact

(PDF) Grinding in Ball Mills: Modeling and Process Control

网页2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made

Contact

(PDF) Modeling and Parameter Identification of Coal Mill

网页2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994). In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup

Contact

Roller Mill Based on Experimental Method mdpi-res

网页2022年1月23日 There are usually four kinds of VRMs in the cement production line, including raw meal mill, coal mill, Clinker Mill and cement mill, and the vertical mill occupies a large energy consumption unit. Therefore, it is necessary to optimize the multi-objective parameters of the VRM in order to improve the grinding performance and reduce energy

Contact

en/manuals search pdf all vertical raw mill.md at main GitHub

网页英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Contact

Vertical Raw Mill for Cement Raw Meal Grinding in Cement

网页Vertical Raw Mill. Feeding size: 35-110mm. Capacity: 12-350t/h. Motor power: 255-3600kW. Applications: It can be used for grinding limestone, gypsum, siliceous, coal and other materials. It is mainly used in cement raw materials grinding section of cement factory, and also be used in concrete and mineral fields. Email: info@ballmillssupplier.

Contact

all parameters for vertical raw mill

网页Not all feed mills, of course, are equipped to pellet feeds. In 1958, these mills produced 40 million tons of feed and about 55% was pelleted. In 1968, about 70% of all commercial produced in the United States was pelleted. In the Midwest, almost 80% of all . ; Used CNC MACHINERY EQUIPMENT For Sale

Contact